helmets and uniforms to indicate the strength of exposure to blasts from explosives in the field.

The badges are comprised of nanoscale structures, in this case pores and columns, that mimic the reflective iridescence of a butterfly’s wing. The tiny shapes, which preferentially reflect certain wavelengths, are sculpted by lasers into a plastic sheet. Douglass H. Smith, MD, director of the Center for Brain Injury and Repair and professor of Neurosurgery at Penn, says that, similar to how an opera singer can shatter glass crystal, these color-changing crystals are designed to break apart when exposed to a blast shockwave, resulting in a substantial color change.

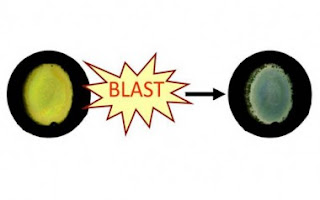

The researchers at the University of Pennsylvania School of Medicine and School of Engineering and Applied Sciences pioneered the microfabrication of three-dimensional photonic structures using holographic lithography. They then made the materials and characterized the structures before and after a blast to understand the color-change mechanism.

“We came up the idea of using three-dimensional photonic crystals as a blast injury dosimeter because of their unique structure-dependent mechanical response and colorful display,” explained Shu Yang, PhD, associate professor of Materials Science and Engineering.

Source: Gizmag